First and foremost, it is important to differentiate the hoist from the winch. The hoist is a lifting tool (vertical axis), unlike the winch which is used to pull loads (horizontal axis).

Hoist and winch are not interchangeable!

Using a winch to lift a load can cause accidents and vice versa!

If you have a bridge crane already set up and just need to replace the hoist, then you’ll already know how your hoist is mounted.

If you don’t, then it must be installed overhead, either in a fixed location or mounted on a trolley by means of a hook or mounting lugs.

A hook mounted hoist is probably the simplest mounting configuration: a hook on the top of the hoist is used to attach the hoist to either a trolley or fixed position on whatever is supporting the hoist.

A hook mounted hoist is probably the simplest mounting configuration: a hook on the top of the hoist is used to attach the hoist to either a trolley or fixed position on whatever is supporting the hoist.

Any type of hoist can have a hook mount, but typically these are for chain hoists. The chain is used because it decreases the swinging of the load.

The hoist frame comes with a lug mounting instead of a hook. A lug-mounted hoist can be securely fastened to a trolley, I-beam, or any other support structure with suitable pins or studs.

The hoist frame comes with a lug mounting instead of a hook. A lug-mounted hoist can be securely fastened to a trolley, I-beam, or any other support structure with suitable pins or studs.

| Hook-Mounted Hoists | Lug-Mounted Hoists |

|---|---|

| Extremely simple | Extremely durable |

| Will last as long as the hoist does | Don’t require much upkeep |

| You might be limited to a fixed position | Better lift |

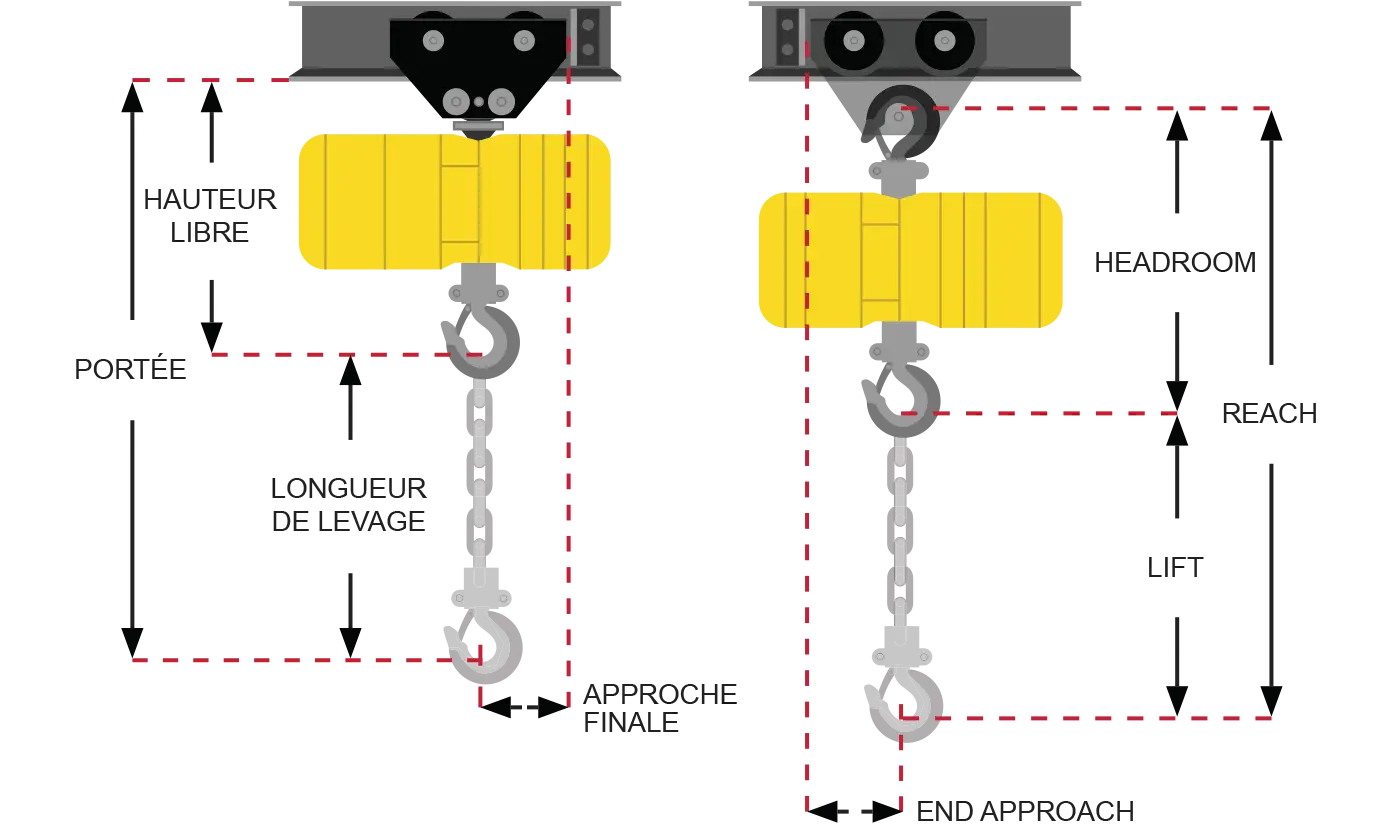

It is the distance the load hook can travel between its fully lowered and fully raised positions.

It is equal to the difference in elevation between the hoist suspension point and the hook saddle in its lowest position.

It is the distance from the hoist suspension point and the fully raised hook saddle. For a hook-mounted hoist, the headroom dimension is the distance between the saddle of the top hook and the saddle of the fully raised lower hook.

It is the distance between the centerline of the lifting hook and the end of a monorail beam, bridge beam or runway on which the hoist is operating. It relates to the ability to center the hoist over the load to be lifted to avoid side pulling.

| Pros | Cons | To Check |

|---|---|---|

| Easy to move, compact and light. | Low lifting speed. | Vertical or inclined load lifting. |

| Lowest purchase price. | For temporary or infrequent use. | The lift and the chain length. |

| Pros | Cons | To Check |

|---|---|---|

| Suitable for frequent use. | Higher purchase price. | Duty class (duty cycles). |

| Faster lifting speeds. | Typically requires 575v voltage. | The power supply (single-phase or three-phase). |

| Designed for high capacities and long lifts. | Not designed to operate continuously. | The environment where it will be used (dust, humidity, etc.). |

| Designed for more precise maneuvers. |

| Pros | Cons | To Check |

|---|---|---|

| Explosion proof (no risk of electrical arcing). | The most expensive to buy. | Requires a compressed air system with air purifier. |

| Lifting speed equal or superior to the electric hoist. | Not portable. | |

| Suitable for intensive and continuous use. | Noisy. | |

| Designed for high capacities and long lifts. | Require a substantial volume of compressed air. |